paving drain channel 1

Project

Project DC/2007/01

Lun Tsuen

New Territories

Hong Kong

System

Grasscrete GC2

Quantity

12,000 m²

Application

Drainage Channel

Downloadable pdf available here back to projects

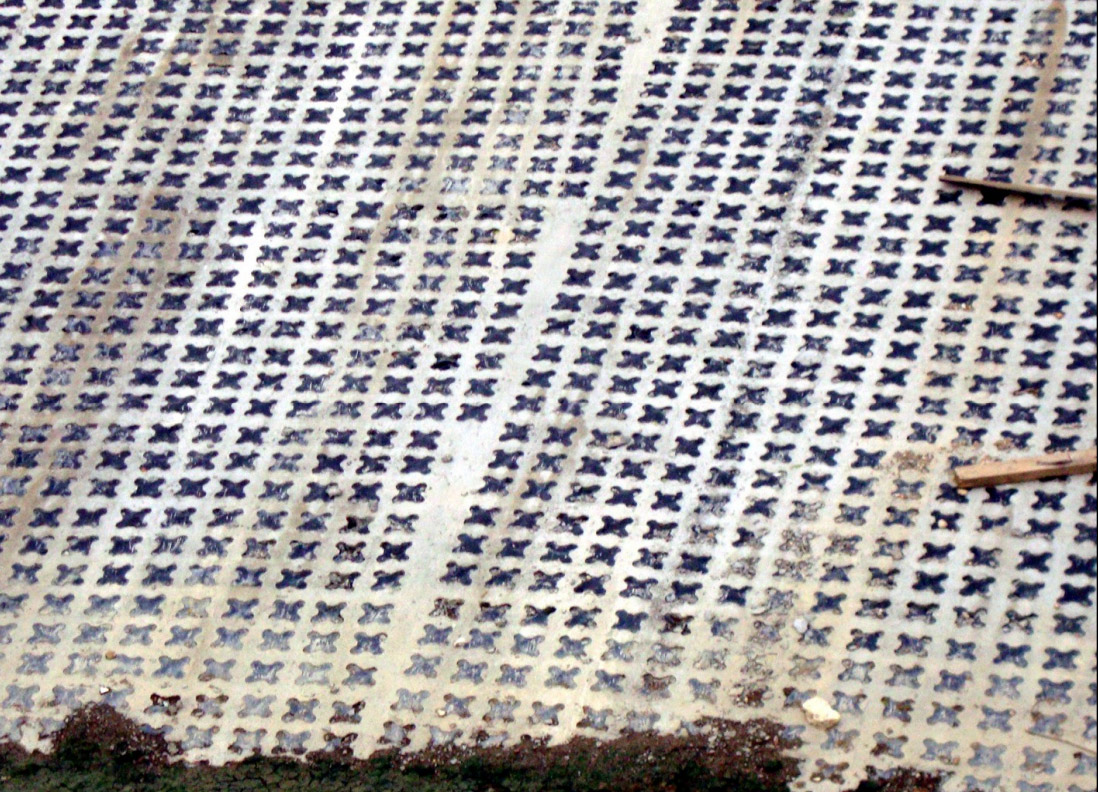

This isn’t perhaps the most photogenic of pictures to include in case study but if it’s true that a picture paints a thousand words then this could be the perfect essay. It sums up the difference between Grasscrete and the pre-cast systems that are often submitted as alternatives and in some cases used, particularly in Hong Kong.

For this example a 2.5km long drainage channel or nullah as it’s known locally winds its way through villages in the New Territories of Hong Kong. In doing so it collects local storm water as part of the Hong Kong Governments Drainage Service Department’s master plan. The curvature dictates that the length of the slope at the top will be different to that at the bottom. Positioning any set module to that means that gaps will occur, even more so when the actual profile of the slope is variable as well. With pre-cast it all becomes a problem as the gaps either have to be infilled with concrete or the blocks themselves have to be mitre cut, with a cellular block is just about impossible.

With a twisting profile these additional labours can be almost as high as the cost of installing the blocks themselves. It also leaves the slope with a series of infill panels that can create turbulent flow and be the cause of breakdown in the armour layer.

As this photo shows Grasscrete doesn’t suffer that problem. Instead the void formers are simply cut and the panel arrange for the best possible fit. When the concrete is then cast the result is an unbroken surface with no structural weakness or unsightly made up joints.

This project uses 150mm thick Grasscrete GC2 with its ability to handle flow up to 8 metres per second.